DryChem's processes and policies are constantly updated and enhanced to reduce environmental impact and promote equitable growth.

We manufacture materials for sturdy structures, and we believe in building stronger communities and nations. Our sustainability programme focuses on three key goals: generating sustainable development while balancing environmental, economic, and social factors.

Social

The philosophy of giving back to the society was laid down by the founder of the company Mr. Ashok Mehta and the company takes the moral responsibility to build a better society through contributing towards community services as well as working towards upliftment and empowerment of the disadvantaged sections of the society.

The Purpose statement of the company since its early days stresses on “To accomplish a positive change in the ecosystem through innovative and reliable partnerships.”

At DryChem, the business priorities coexist with the commitment to identify the needs of the surrounding communities. In addition to developing and adopting an effective CSR approach to implementing multiple interventions in the region surrounding our business and plant locations, to make a sustainable impact.

The major CSR thrust areas are Education and Health.

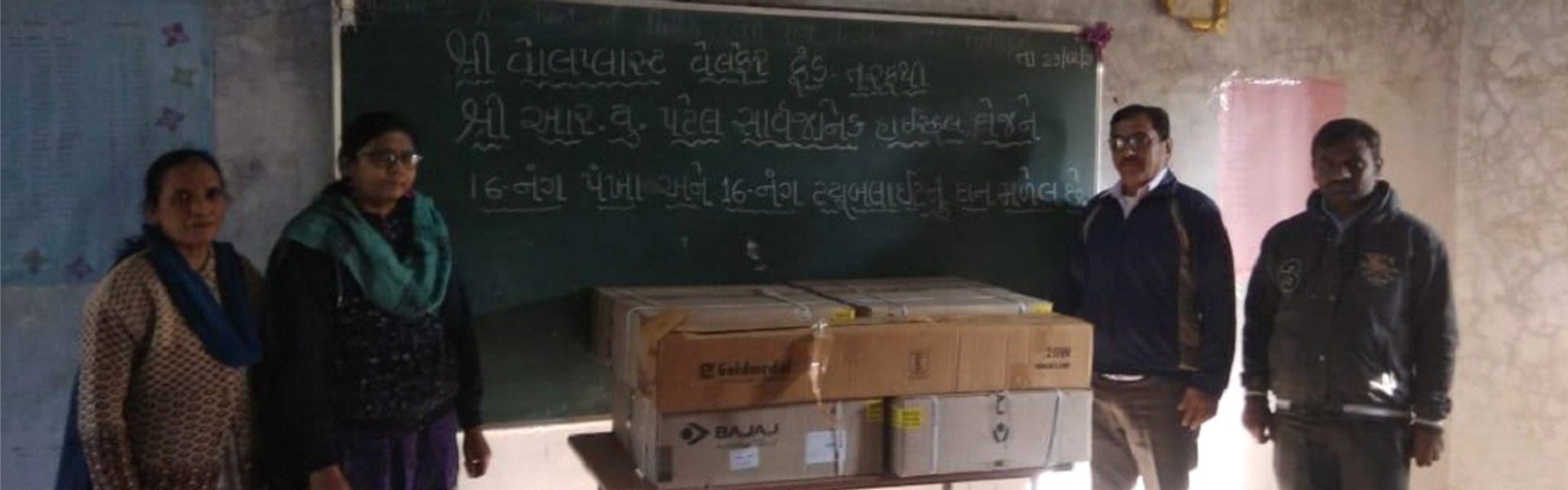

Education: 80% of the focus area of DryChem CSR activities is Education. The company supports schools in the vicinity of its factories, to enhance the learning of the students.